The 1st MPRC Competition

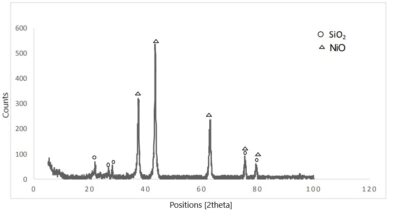

In the summer of 2017, two of my friends and I got interested in taking part in this competition for the first time. Challenge of the competition was “Recovery of nickel from spent hydrogenation catalyst of food industries”. XRF and XRD analyses results of this waste were as follow:

| compound | NiO | SiO2 | Fe2O3 |

Al2O3 |

| % | 36 | 29.2 | 2.8 | 1.3 |

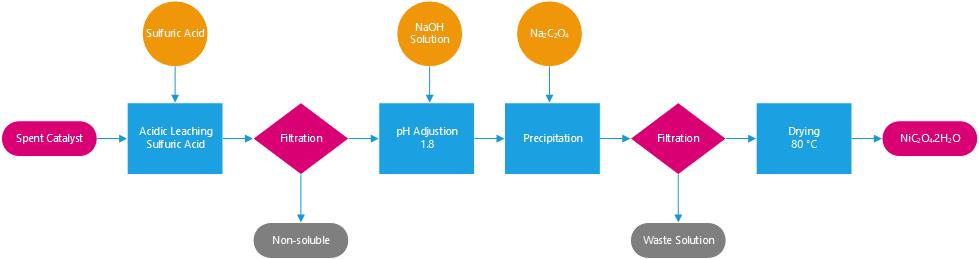

Based on material characterization, we must suggest a hydrometallurgical process using normal chemicals and facilities to reach a solid product within 6 hours (max). Therefore, we designed a process by studying scholar publications in this topic and consulting with our professors. Below flowchart shows schematic of this process. Suggested process included a regular leaching in sulfuric acid medium followed by filtration and pH adjusting. Next step was what distinguished us from other groups. At this step, we used oxalate as a precipitant agent because it caused precipitation of Ni while other impurities remained soluble in solution. This step was the most investigated part in our work because different compounds of oxalate anion have been reported to have different behaviors, for example introducing its compound with K makes a double salt of Ni and Fe that reduces final quality.

At the end of competition, performance of teams was evaluated based on following criteria:

- Written proposal,

- Suggested process,

- Simplicity, time, cost, efficiency, and Sustainability.

- Product,

- Application, value, and quality.

- Oral presentation.

We presented an outstanding performance and, in this regard, we succeeded to be selected by the referee committee as the best team between 8 participants.

A shout-out to my exceptional teammates, engineers Karimi and Farahani who did their best. I wish them all the best in their future endeavors.

Leave a Reply